The process of making Dienstmütze is not easy – and not fast. It requires lots of hand-sewing, that is even not visible in the final product.

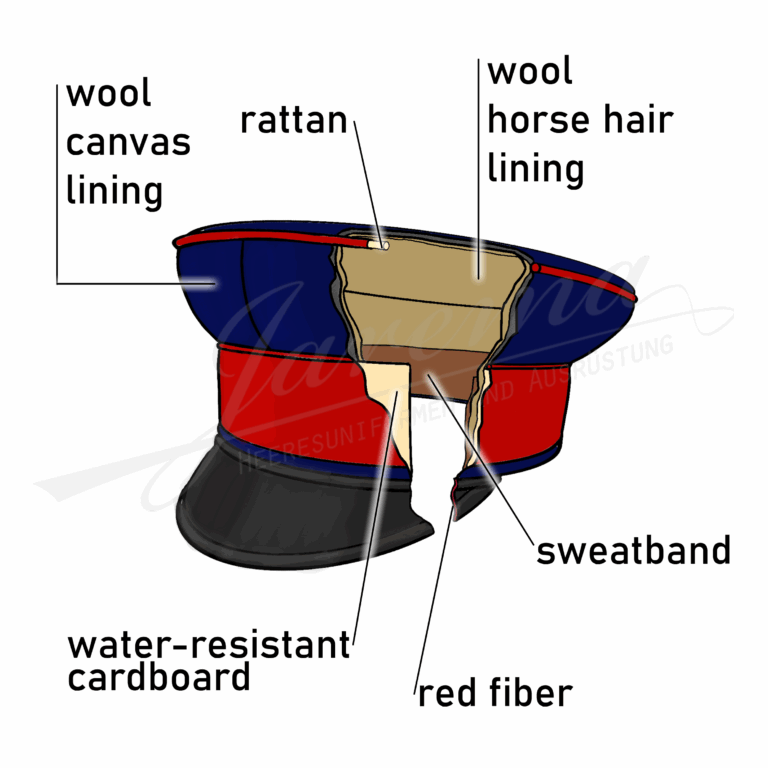

A cross-section of a cap with the layers:

A “rattan” is the name of many species of climbing palms that can be found mostly in Southeast Asia. It is used for furniture, woven mats and basket making.

It is stiff, yet flexible, and can be easily formed when wet (like wicker).

It was used by German cap makers since 18th century (at least till the end of WW2) in crown piping. Other materials could’ve been used as well, i.e. metal wire, cotton cord, etc.

The crown can be additinally stiffened with metal wire. (I use plastic underwire, as it is impossible to get flat spring wire in proper size)

The visors are made of red fiber (vulcanized fibre), that is basically laminated cellulose. It is used in insulating (as it is water-resistant and doesn’t conduct electricity). The fiber is cut to the shape and then pressed for more durability. After that the visors are painted (black or feldgrau outside and lining color inside). Sometimes the insides of the visor were left unpainted

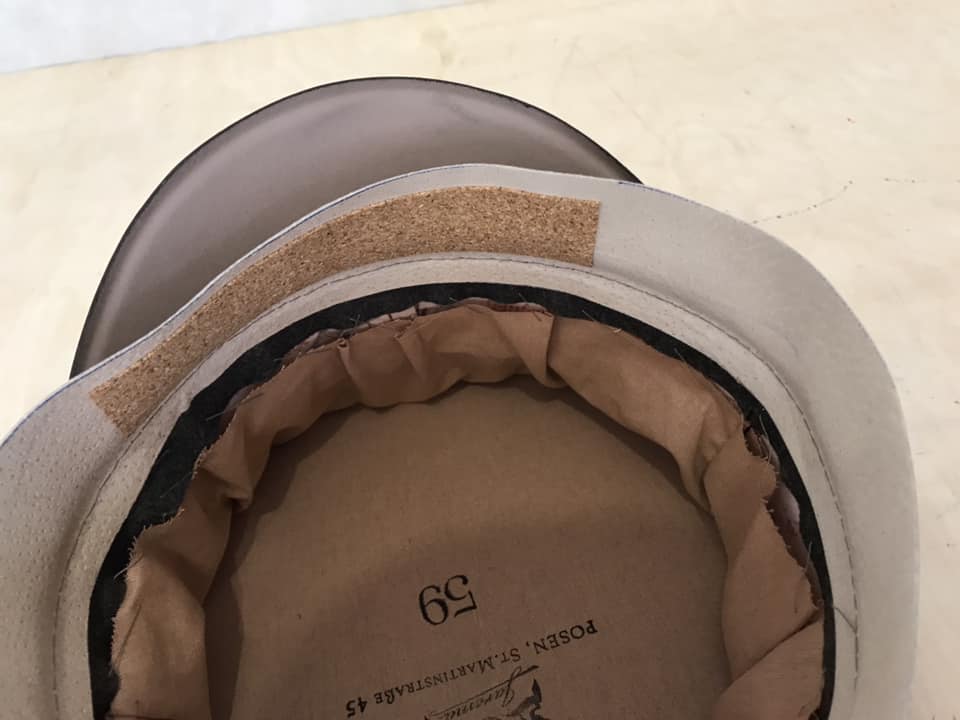

Sweatband is made of artificial leather (can be made of oilcloth or natural leather as well) and sometimes is lined with cork.

The overall shape differs between the caps. The fashion changed, so you can see tiny crowns, very tall ones, and even some in the shape of Tellermütze. Moreover, in early 1940s a new “saddle” shape was introduced.

“Standard” (at least most popular) shape without additional stiffener in the crown

High crown with additional internal stiffeners and wire in the crown

WW2 “saddle” shape